www.micoope.com.gt

www.micoope.com.gt Opening: Embark on a Rowing Adventure with Your Own DIY Rowboat! Building a rowboat is a rewarding project that allows you to connect with traditional craftsmanship, enjoy the open water, and save money compared to purchasing a pre-made boat. This step-by-step guide will walk you through the process, from gathering materials to launching your handcrafted vessel. Prepare to get your hands dirty and experience the satisfaction of creating something truly unique.

Step 1: Gathering Your Supplies and Tools Before you begin, you'll need a comprehensive set of materials and tools. This preparation is key to a smooth and successful build. Wood: Marine-grade plywood (typically ¼" or 6mm thick) is the standard choice for its water resistance and strength. The amount you need will depend on the size and design of your boat. Epoxy Resin and Hardener: This will be used to bond the wood together and create a waterproof seal. Choose a marine-grade epoxy for best results. Fiberglass Cloth: Used in conjunction with epoxy to reinforce seams and vulnerable areas. Fasteners: Copper wire (for stitching the hull panels together), stainless steel screws, and epoxy glue. Paint/Varnish: To protect the wood from the elements and give your boat a beautiful finish. Marine-grade varnish is recommended. Tools: Saw (jigsaw, circular saw, or handsaw), drill, sander, measuring tape, clamps, mixing containers and sticks for epoxy, brushes, safety glasses, gloves, and dust mask.

Step 2: Preparing the Hull Panels This involves cutting out the individual pieces that will form the hull of your rowboat. Obtain Plans: Begin with a set of rowboat plans. Many free and paid plans are available online. Choose one that suits your skill level and desired boat size. Transfer Patterns: Carefully transfer the patterns from the plans onto your plywood sheets. There are several methods: using carbon paper, tracing, or creating templates. Accuracy is crucial for a well-fitting boat. Cut the Panels: Using your chosen saw, carefully cut out the hull panels according to the patterns. Take your time and cut precisely along the marked lines. Sand the Edges: Sand the edges of the panels smooth to remove any splinters or imperfections. This will ensure a tight and clean fit when you assemble the boat.

Step 3: Stitching the Hull Together This is where the flat panels begin to transform into the shape of a boat. Drill Stitch Holes: Drill small holes along the edges of the panels where they will be joined. These holes will be used to "stitch" the panels together with copper wire. Follow the spacing indicated in your plans. Stitch the Seams: Using copper wire, carefully stitch the panels together, starting at the bow and stern. Twist the wire ends tightly to hold the panels in place. Check the Shape: As you stitch, constantly check the shape of the hull against the plans to ensure it is conforming to the design. Make any necessary adjustments.

Step 4: Applying Epoxy and Fiberglass This step bonds the panels permanently and creates a waterproof barrier. Prepare the Epoxy: Mix the epoxy resin and hardener according to the manufacturer's instructions. Be precise with the mixing ratios. Apply Epoxy to the Seams: Apply a generous bead of epoxy along the inside of the stitched seams. Use a mixing stick or brush to smooth the epoxy and ensure it fills the gaps. Apply Fiberglass Tape: Apply fiberglass tape over the wet epoxy along the seams. This will reinforce the joints. Use a brush to saturate the fiberglass with more epoxy. Remove Stitching: Once the epoxy has cured, carefully remove the copper wire stitches. Sand Smooth: Sand the fiberglassed seams smooth to blend them with the surrounding wood.

Step 5: Adding Structural Elements and Interior Components This strengthens the hull and adds functionality. Install Frames and Bulkheads: Add any frames or bulkheads specified in your plans. These provide additional support to the hull. Install Seats and Thwarts: Install seats (if any) and thwarts (crossbeams) for structural support and to provide seating. Apply Additional Epoxy and Fiberglass: Apply epoxy and fiberglass to any additional areas that require reinforcement, such as the keel.

Step 6: Finishing and Painting This protects the boat from the elements and gives it a professional look. Sand the Entire Boat: Thoroughly sand the entire boat to prepare the surface for painting or varnishing. Apply Primer: Apply a coat of marine-grade primer to the boat. Paint or Varnish: Apply several coats of marine-grade paint or varnish, allowing each coat to dry completely before applying the next.

Step 7: Launching Your Rowboat The moment you've been waiting for! Inspect the Boat: Before launching, carefully inspect the boat for any leaks or imperfections. Add Oars and Life Jackets: Equip the boat with oars and life jackets. Launch and Enjoy! Launch your boat in calm water and enjoy the fruits of your labor!

Conclusion: A Labor of Love, A Source of Pride Building a rowboat is a challenging but incredibly rewarding experience. You've not only created a functional vessel but also honed your woodworking skills and connected with a rich maritime tradition. Enjoy the open water in your handcrafted rowboat, knowing you built it yourself!

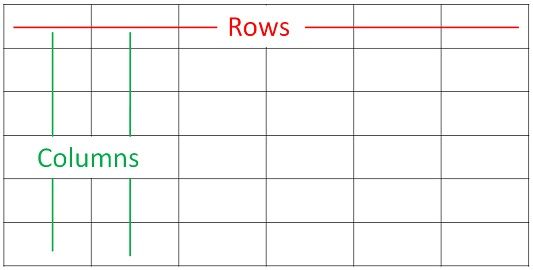

What Is Row In Math? Definition, Examples, Uses, Facts, 42% Off

www.micoope.com.gt

www.micoope.com.gt Using Columns And Rows Handsontable 12.2.0: More Flexibility In Adding

fity.club

fity.club Row

www.picnbooks.com

www.picnbooks.com

0 komentar:

Posting Komentar